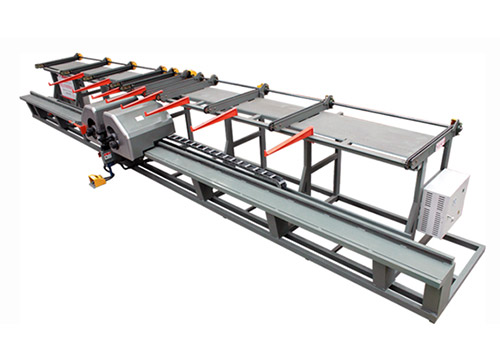

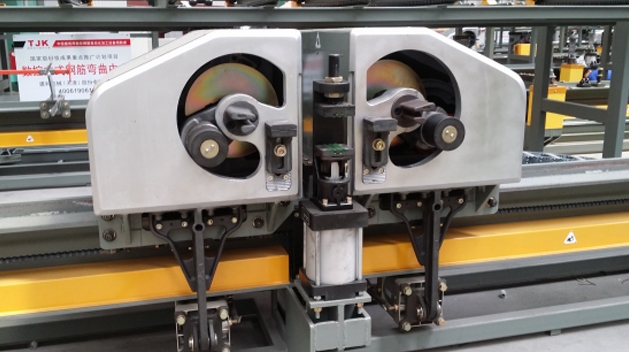

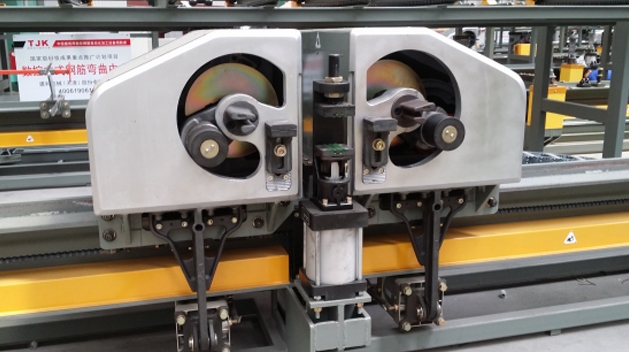

Features of Rebar Bending Line G2L32E-2 (10-32 mm)

|

The whole machine without air, avoid the air leakage, pollution and other issues, easy for maintenance; |

| The integrated Machine structure, easy transportation, fast installation and debugging; |  |

|

Gear rack drive, positioning accuracy, low noise; |

| Electric chain rail material storage conveyor platform, take material save effort; |  |

|

Only one person operation, high production efficiency; |

| Processing the largest diameter is 32mm; |  |

|

Equipment has a test function, to achieve bending steel no waste; |

Dimensions of Rebar Bending Line G2L32E-2

11500X2100X1500 (mm) The whole structure of the machine, easy transport, no need fixed, full mechanical transmission structure, no need gas source, low noise, easy maintenance, mechanical and electrical integration design, advanced control module, The equipment head movement is equipped with a test function ,to achieve the bending steel generated; can achieve two-way automatic bending of the steel bar, the workpiece can be used to improve the size of the workpiece, The maximum diameter of the curved bars is ø32.

Characteristics of Rebar Machinery Rebar Bending Line G2L32E-2

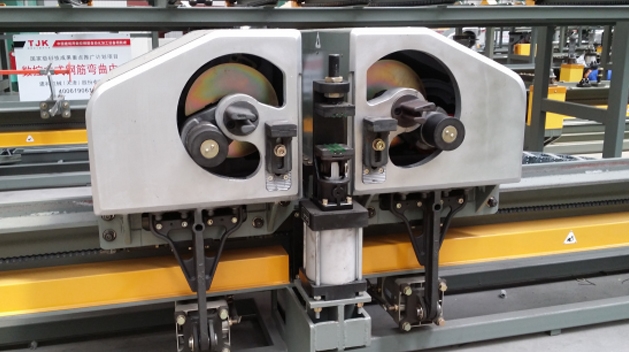

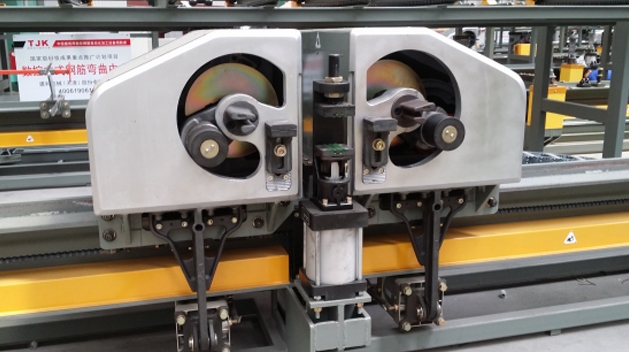

Rebar Bending Line G2L25/G2L32E-2(bar benders) has advanced technology is introduced from Europe,lots of parts have patent for invention, the high efficiency also high endurance and humane designings are safe and reliable;

High precision of PLC control,it is powerful database inside, no need manual adjustment;

Rebar Bending Line G2L25/G2L32E-2(bar bender machine) is precisely working with angle,maximum diameter for bending is 32 mm;

Rebars can be bent by double-shaft, workable of direction from forward and reverse; More than one rebar can be bent at the same time,bending range 0°-180°;the service life and efficiency are greatly improved by the bending units which made by special materials;the workers safety are ensured by the covering of the machine(bar benders) ;

TJK CNC Rebar Bender Line G2L25/G2L32E-2(bar benders) have been sold more than 300 pcs around the world

Technical Data of Rebar Bending Line G2L32E-2

| Bending capacity | Clockwise: Φ10 – Φ25 [mm] Anti-clockwise: Φ10 – Φ32 [mm] |

|||||||||

| Max. bending angle |

Clockwise: 120° Anti-clockwise: 180° |

|||||||||

| Max. bending sides length |

10 [m] | |||||||||

| Min. bending side length |

Φ10mm 560mm | |||||||||

| Φ32mm 620mm | ||||||||||

| Min. bending hook length | 80 [mm] | |||||||||

| Bender move speed |

0.5 – 1 [m/s] | |||||||||

| Bending speed | 48-72°/S | |||||||||

| Installed power | 10.5 [KW] | |||||||||

| Air pressure | ≥ 0.6 [Mpa] | |||||||||

| Average power consumption |

4 [KW/h] | |||||||||

| Voltage | 380 [V] – 50[Hz] | |||||||||

| Overall weight | 5500 [KG] | |||||||||

| Overall diameter | 11050X2100X1520 [mm] | |||||||||

| Bars diameter (max tensile strength 750Mpa |

Φ10 | Φ12 | Φ14 | Φ16 | Φ18 | Φ20 | Φ22 | Φ25 | Φ28 | Φ32 |

| Bending bars no° | 6 | 5 | 4 | 3 | 2 | 2 | 2 | 1 | 1 | 1 |