Features of Stirrup Bender WGZ12B

|

Precut steel bar 6-14mm is workable, max wire length up to 1700mm ; Duplex bending axis set being used, a variety of molds are available for making different sizes of stirrups, workable with “8” type stirrups; |

| Automatic wire feeding system which designed with accurate guide position and counting detection mechanism, it making automatically put the steel from the feed port automatically sent to the host, the automatic wire can be completed within 2 seconds, simple and reliable operation, greatly improving the straight bar steel processing effectiveness; |  |

|

Machine has disc bending mechanism which avoids the stirrups collision and ensures the product pass rate of 100%; Equipped with multitasking optimization of steel, you can maximize the use of the entire wire; |

Features of Stirrup Bender WGZ12B

1. Rebar cutter and bender WGZ12B has 7 kinds of Mandrel units ensure the variety of products, minimum bending size 100X100mm;

2. Automatic feeding unit will feed the steel bars from inlet into the machine, it has precisely guided and counting units, feeding will be finished in 2 seconds;(UNIQUE TECHNOLOGY)

3. Designed for dust proof and enclosed type, operational safety, prolong service life by 50%;

4. Stirrup steel bar Bender WGZ12B designed of optimization of materials, maximum the utilization of steel bar.

Technological Design Characteristic of Stirrup Bender WGZ12B

1. Anti-skid slot on the driving wheels will prevent the steel bar from skidding;unti-loose and tightening technology are used on the end-face key, encoder equipped to ensure precision of ±1m;

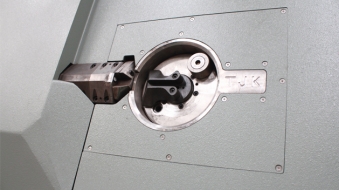

2. Disc- type bending unit made of stainless steel to avoid collision and ensure 100% qualification rate.(UNIQUE TECHNOLOGY)

3. Split type designed fixing cutter is easily maintained; Fixing cutter can be used both sides, prolonged service life; All four sides of mobile cutter can be used, prolong service life 4 times, greatly decreased customer’s cost.(UNIQUE TECHNOLOGY)

Advantages of Technical Data of Stirrup Bender WGZ12B

1. Steel Stirrup Bender WGZ12B cutting unit is high-speed mechanical type, only need 0.45S of one cut, have passed 300 thousand times of high-frequency and rough condition operation test;

2. Capable operation with new Chinese 3rd class rebar, anti overloading, resists high temperature;

3. Driven by full closed loop type high precision servo motor ensure the length accuracy of ±1mm, angle accuracy ±1°;

4. Mandrel and molds on the bending unit, ensure the minimum side of rebar 100mm.

Features of Control System

International brand controller, HMI and Servo.

4 groups data base. Capable store 500 graphs.

2 Ethernet interface model RJ45, I+II type CF card slot.

Remote Internet diagnosis and program update function.

Features of mechanical parts

1. Cutter is made of alloy mould steels, follow the international acceptance standard of NADCA207, the quality is 50%-80% higher than similar products in the world.

2. Made by the special heat-treatment process, ensure the cutter quality, prolong the service life to more than 100 thousand which is 10 times of normal kind die steels.

3. The driving wheel is made of new type high alloy wear-resistant steel, the level of material is 3 times higher than Chinese standard, vacuum heat-treatment is being used to ensure the wearability is 30%-50% higher than other high quality die steels, the quality is 3-5 times higher than normal kind of die steels.

Features of Processing Technology

Steel bar bending machine WGZ12B has fully automatic CNC laser cutting center, the automatic welding robot, hundred of high precision vertical and horizontal machining center, ensure high precision machining, 100% exchanging rate.

Net Communication

Capable of connecting with Independent R &D TJK MAX MES system, high-efficiency operation, the system can be updated.

Technical Data of Stirrup Bender Rebar Bender and Cutter WGZ12B

| Production capacity Single wire | Φ6 – 14 [mm] |

| Double wires | Φ8 – 10 [mm] |

| Max. bending angle | ±180° [double direction] |

| Max. bending speed | 1200 [°/sec] |

| Max. pulling speed | 110 [m/min] |

| Mandrel diameter | Φ25 – Φ30 [mm] |

| Max. length of the stirrup side (diagonal) | 1700 [mm] |

| Min. length of the stirrup side | 100 [mm] |

| Length tolerance | ± 1 [mm] |

| Bending tolerance | ± 1° |

| Average electric power consumption | 4 [KW] |

| Labeled electric power | 17 [KW] |

| Voltage | 380 [V] – 50 [Hz] |

| Overall machine weight | 2590 [Kg] |

| Overall dimension | 3100X1200X2100 [mm] |