Features of Truss Girder Welding Machine SJL320T-36

|

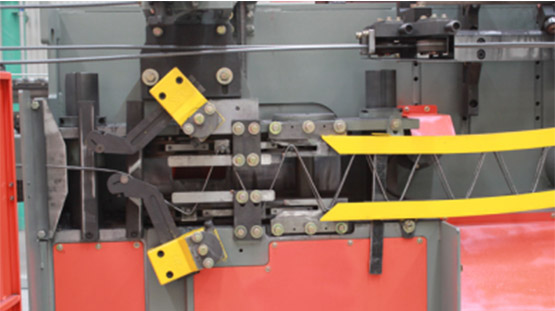

Wire feeding and steel bar buffering device can avoid the problem of abnormal steel bar setting out at high speed step feeding. |

| The passive step feeding system can increase production by 20%-30% compare to other suppliers, feeding speed max 30m/min. |  |

|

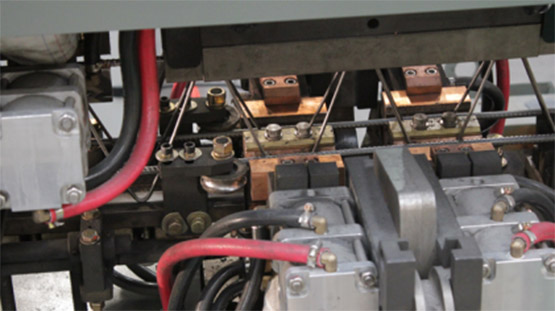

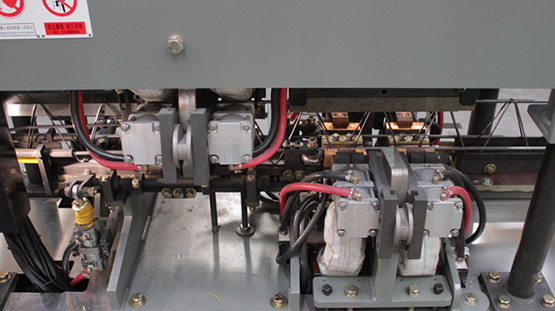

Optional four point or two point resistance spot welding method can solve the problem of unstable or insufficient external voltage, and each welding spot welding parameters can be set separately. |

| The square type electrode head can be reused 4 times, and the use cost is reduced by 3 times. |  |

|

The wire breaking alarm device can avoid the waste of manpower and time of re feeding, and each shift will save 2 hours. |

| Shearing method is mechanical which replaced hydraulic which save cost of maintenance and hydraulic oil, also avoid oil licking and noise. |  |

|

Installed power 640kW, 20% lower than other suppliers. |

More Detail Truss Girder Welding Machine SJL320T-36

Truss girder welding machine is controlled by high-precision PLC which is also high production, high speed, high durability, high wel ding quality, input through touchable screen which is easy operation and equipped with powerful data base. Girder height 70-320 mm, length 2-14m (multiple of 200mm), speed up to 36 m/min, it owns many patents.