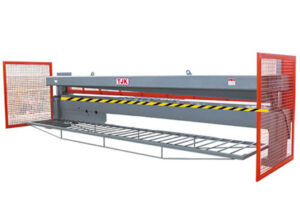

Features of Engineered Mesh Welding Line GWCAK3300

|

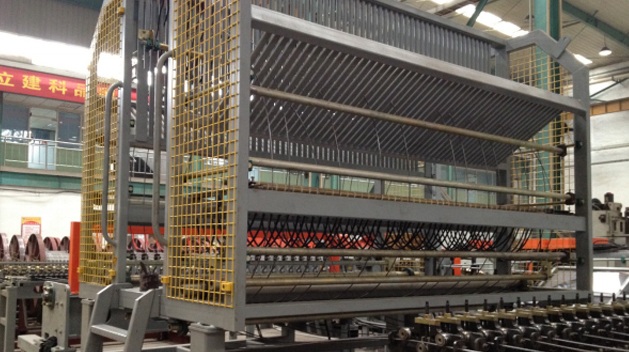

The modular system can finish the precise adjustments according to the special requirements, 4 kinds of wire rods will be fully automatic straightened, cut, welded, formed, during the whole process wires can be changed at any time, and the welding current and welding pressure will be changed |

| No need to follow the standard mesh size for high-cost tailoring; IF inverter welding ensures a very low external 350KVA load power; |  |

|

Welding electrodes and transformers are all cooled by forced water cooling, electrode life increased by 50% compare to non-water cooling, welding quality increased by 80% ; |

| Cutting knife is made of high toughness alloy die steel, acceptance standards in strict accordance with international standards NADCA207, material performance is much higher than the same national standard level by 50% -80%; |  |

More Detail Engineered Mesh Welding Line GWCAK3300

Highly flexible and fully automatic welding line for the production of mesh sheets and reinforcing elements allowing processing different wire diameters and producing different openings.

Technical Data of Engineered Mesh Welding Line GWCAK3300

| Mesh Width | 1500-3300 mm |

| Mesh Length | 2000-8000 mm |

| Opening Mesh Length | Min 500 mm |

| Gap between Line Wires(Coil) | Min 50mm, In Multiple of 50 mm |

| Gap between Cross Wires(Coil) | ≥50 mm, Infinitely Adjustable |

| Diameter and Wire Material | Φ5-12 mm, Cold rolling and hot rolling ribbed wire |

| Max Welding Speed | 45 strokes/min |

| Welding Method | Intermediate Frequency (Pneumatic Type) |

| Controlling Method | Industrial PLC+Industrial Computer |

| Power | 1000 KVA |

| Number of Welding Spot | 32 |

| Machine Size | 34000 x 9500 x 4415 mm |