Features of Stirrup Bender WG12B-2

|

Working angle can be rotated ensures a larger processing range, the max length of stirrup up to 2300mm; |

| It has automatic wire feeding system, shorten feeding time to 5 seconds, saved lots of time. |  |

|

Straightening memory straight roll is being used, more convenient replacement of wire changing; |

| Fixed cutter can be used on both sides to improve the service life; cutting knife is designed with four available sides, service life increased by 4 times, greatly reducing costs. |  |

|

Driven by full-closed-loop control servo motor which has high-precision, ensures the accuracy of length of ± 1mm, angle accuracy of ± 1 ° |

More Detail Stirrup Bender WG12B-2

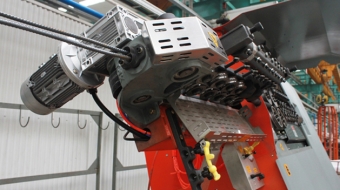

Stirrup Bender WG12B-2(stirrups rebar) has the particular patented straightening system, constituted by sets of horizontal and vertical rollers that can be automatically adjusted, is integrated with 4 pulling rollers that eliminate the torsion, which is driven by servomotor, thus ensuring a perfect straightening accuracy.

The bending and cutting unit of Stirrup Bender WG12B-2(stirrups rebar), driven by servomotor, is equipped with turning and retractile bending pins. After receiving a signal from the computer, the cutting unit starts and cut in the twinkling guaranteed the tolerance of the stirrup.

For this Stirrup Bender WG12B-2(stirrups rebar), many electric and pneumatic parts are imported from Japan and German, such as PLC, servomotor and reducer.

A Stirrup Bender WG12B-2(stirrups rebar) available to the most 30 bends; 500 different stirrups parameter can be stored in the computer memory.

The Stirrup Bender WG12B-2(stirrups rebar) needs no pause and stop while processing stirrups of any shapes and adjusting bending angle.

Technical Data of Stirrup Bender WG12B-2

| Production capacity | Single wire | Φ5 – 13 [mm] |

| Double wire | Φ5 – 10 [mm] | |

| Max. bending angle | ±180° [double direction] | |

| Max. bending speed | 1200 [°/sec] | |

| Max. pulling speed | 110 [m/min] | |

| Mandrel diameter | Φ25 – Φ32 [mm] | |

| Max. length of the stirrup side (diagonal) | 2,300 [mm] | |

| Min. length of the stirrup side | 120 [mm] | |

| Length tolerance | ± 1 [mm] | |

| Bending tolerance | ± 1° | |

| Average air-compressed consumption | 6 [l/min] | |

| Average electric power consumption | 6 [Kw/h] | |

| Labeled electric power | 28 [Kw] | |

| Voltage | 380 [v] – 50 [Hz] – 3[phase] | |

| Overall machine weight | 4,800 [Kg] | |

| Overall dimension | 5,100 × 1,300 × 2,100 [mm] | |