Features of Wire Straightening and Cutting Machine GT3-7

|

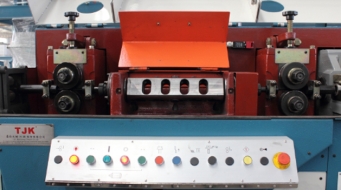

Servo motor cutting technology being used, timing belt drive, high accuracy positioning, no noise; workable with wire min length 800mm, stable quality, maintenance-free; |

| Straightening process and conveying mechanism are controlled by CNC system, straightening speed and conveying speed can be step-less adjusted, little damage on steel surface; high straightening speed and straightness, high production and safety, instant braking; |  |

|

A group of workers can operate two machines which are placed in positive and negative side, overall size small, increased production efficiency; |

| Discharge mechanism may be quickly opened and closed, a simple structure unloading rack being used, which ensures greatest convenience hoisting of finished products; |  |

|

The steel straightening process is visible, the cover is installed with tempered glass, feeding, transport and shearing process can be observed without stop; |

Characteristics of Wire Straightening and Cutting Machine GT3-7

Wire Straightening and Cutting Machine GT3-7(automatic wire cutter machine) fast in straightening and cutting: Our product could reach the highest straightening and cutting speed of 100m/min, 3-4 times that of domestic similar products.

Automatic Wire Straightening and Cutting Machine GT3-7(automatic wire cutter machine) Suitable for new 3rd-grade steel: The straightening performance of our products is unique, and suitable for straightening and cutting cold rolled ribbed steel bar and new 3rd-grade steel which is promoted by the government.

Automatic Wire Straightening and Cutting Machine GT3-7(automatic wire cutter machine) intelligent control: We adopt PLC to control. Operate, regulate and remote control, which is easy and reliable.

Technical Data of Automatic Wire Straightening and Cutting Machine GT3-7

| Raw material | Plain or deformed wire rod in coil (low carbon) |

| Production capacity | Φ3 – Φ7 [mm] (tensile strength≤500mpa) |

| Straightening speed | 30-100 [m/min] (AC Frequency convert control) |

| Cutting length | 800 – 3,000 [mm] |

| Cutting method | Servo motor control |

| Length gauge | Manual |

| Linearity of straightening | ≤2 [mm/m] |

| Tolerance of cut-to-length | ≤ ±1 [mm] |

| Total power | 22.5 [Kw] |

| Total weight | 2,000 [Kg] |

| Overall dimension | 12,000mm(l) × 1,500m(w) × 1,700m(h) |