Features of Wire Mesh Welding Machine GWC 2400/2800/3300

|

Line wires will be fed into welding point automatically by servo motor.While welding, a next batch line wires can be loaded and fed. It makes the production continuous. |

| Welding system is designed for the deformed and plain wire. |  |

|

Welding transformers are water cooled and a thermostat monitors over-heating. |

| Maximum welding speed 60–90 strokes per minute. |  |

|

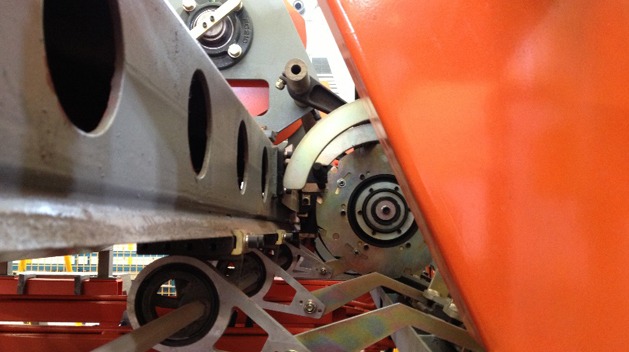

Automatic cross wire feeding which is driven by the servo motor. |

Characteristics of Wire Straightening and Cutting Machine GT5-12Q

Wire Straightening and Cutting Machine GT5-12Q (wire straightener) fast in straightening and cutting: Our product could reach the highest straightening and cutting speed of 130m/min, 3-4 times that of domestic similar products.

Automatic Wire Straightening and Cutting Machine GT5-12Q (wire straighteners) Suitable for new 3rd-grade steel: The straightening performance of our products is unique, and suitable for straightening and cutting cold rolled ribbed steel bar and new 3rd-grade steel which is promoted by the government.

Cutting Machine GT5-12Q (wire straightener) intelligent control: We adopt PLC to control. Operate, regulate and remote control, which is easy and reliable.

Technical Data of Automatic Wire Straightening and Cutting Machine GT5-12Q

| Raw material | Smooth and ribbed wires in coil (low carbon) |

| Production capacity | Φ5 – Φ12 [mm] (cold rolled) Φ5 – Φ10 [mm] (hot rolled ribbed) |

| Maximum straightening speed | 130 [m/min] (AC Frequency Convert Control) |

| Cutting length | 800 – 12,000 [mm] |

| Cutting method | Servo motor |

| Length gauge | Manual |

| Linearity of straightening | ≤2 [mm/m] |

| Tolerance of cut-to-length | ≤±1 [mm] |

| Total power | 49.5 [Kw] |

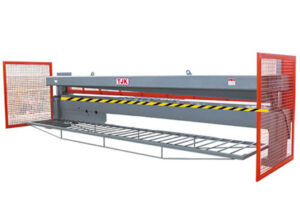

| Overall dimension | 23 × 2.6 × 1.7 [m] (L×W×H) |